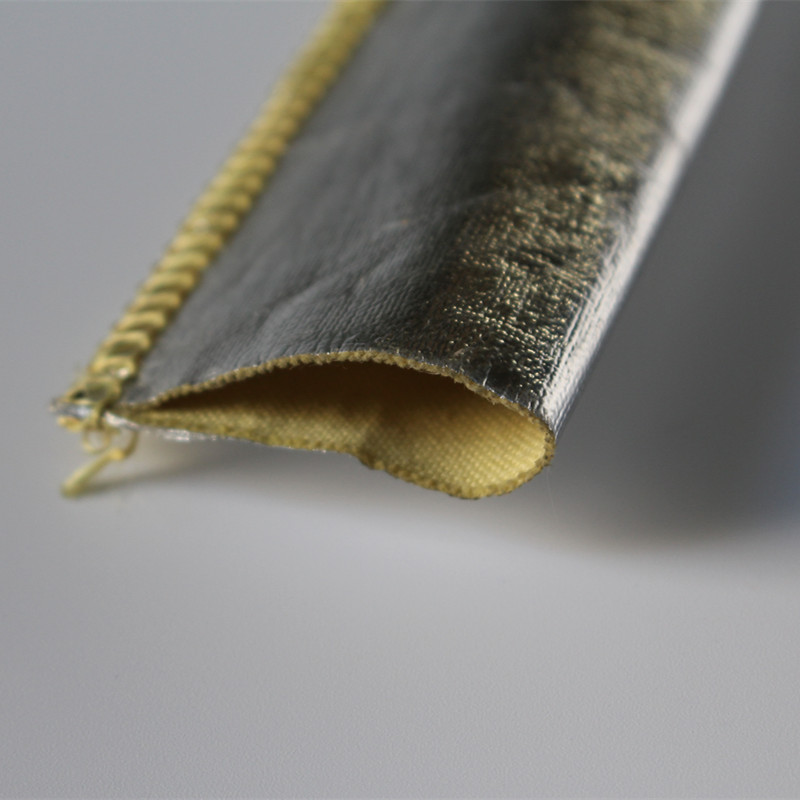

Alüminize Kevlar ısı kılıfı, aşırı sıcaklıklara ve zorlu koşullara dayanacak şekilde tasarlanmış, üstün termal koruma ve dayanıklılık için tasarlanmıştır. Yüksek mukavemetli Kevlar taban ve alüminize dış katmandan oluşan bu kılıf, mükemmel aşınma ve kesilme direnci sunarken radyant ısıyı yansıtır. Yüksek ısıya maruz kalan hortumları, telleri ve bileşenleri korumak için otomotiv, havacılık ve endüstriyel uygulamalarda yaygın olarak kullanılmaktadır.

Temel Performans Özellikleri

Gerçek Dünya Uygulamaları

Otomotiv endüstrisinde alüminize Kevlar ısı kılıfları genellikle yüksek performanslı araçlardaki yakıt hatlarını, kabloları ve hortumları korumak için kullanılır. Bir yarış arabası teknisyeni şunu paylaştı: "Alüminize Kevlar ısı manşonunu kullanmak bizim için oyunun kurallarını değiştirdi. Yakıt hatlarımızı ısı hasarından koruyarak pistte tutarlı performans sağlıyor."

Havacılıkta bu manşon, uçak motorlarındaki ve egzoz sistemlerindeki bileşenlerin yalıtımı için kritik öneme sahiptir. Bir havacılık ve uzay mühendisi şunu belirtti: "Yüksek sıcaklıktaki bölgelerde hassas kabloları korumak için bu kılıfa güveniyoruz. Isıya maruz kalmanın neden olduğu arıza riskini önemli ölçüde azaltır."

Endüstriyel uygulamalarda, fırınların yakınında veya aşırı koşullarda çalışan borular, vanalar ve ekipmanlar için izolasyona uygulanır. Bir tesis yöneticisi şunu belirtti: "Kevlar ısı manşonu, makinelerimizin ömrünü büyük ölçüde artırdı. Isıya ve aşınmaya karşı dayanıklıdır, bakım ve değiştirme maliyetlerini azaltır."

Avantajları

Sonuç

alüminize Kevlar ısı kılıfıYüksek ısılı ortamlarda olağanüstü termal koruma arayan herkes için nihai çözümdür. Isı direnci, dayanıklılık ve hafiflik esnekliğinin birleşimi onu otomotiv, havacılık ve endüstriyel uygulamalar için vazgeçilmez kılmaktadır. Yakıt hatlarını korumak veya hassas kabloları yalıtmak olsun, bu kılıf benzersiz performans ve güvenlik sunar.