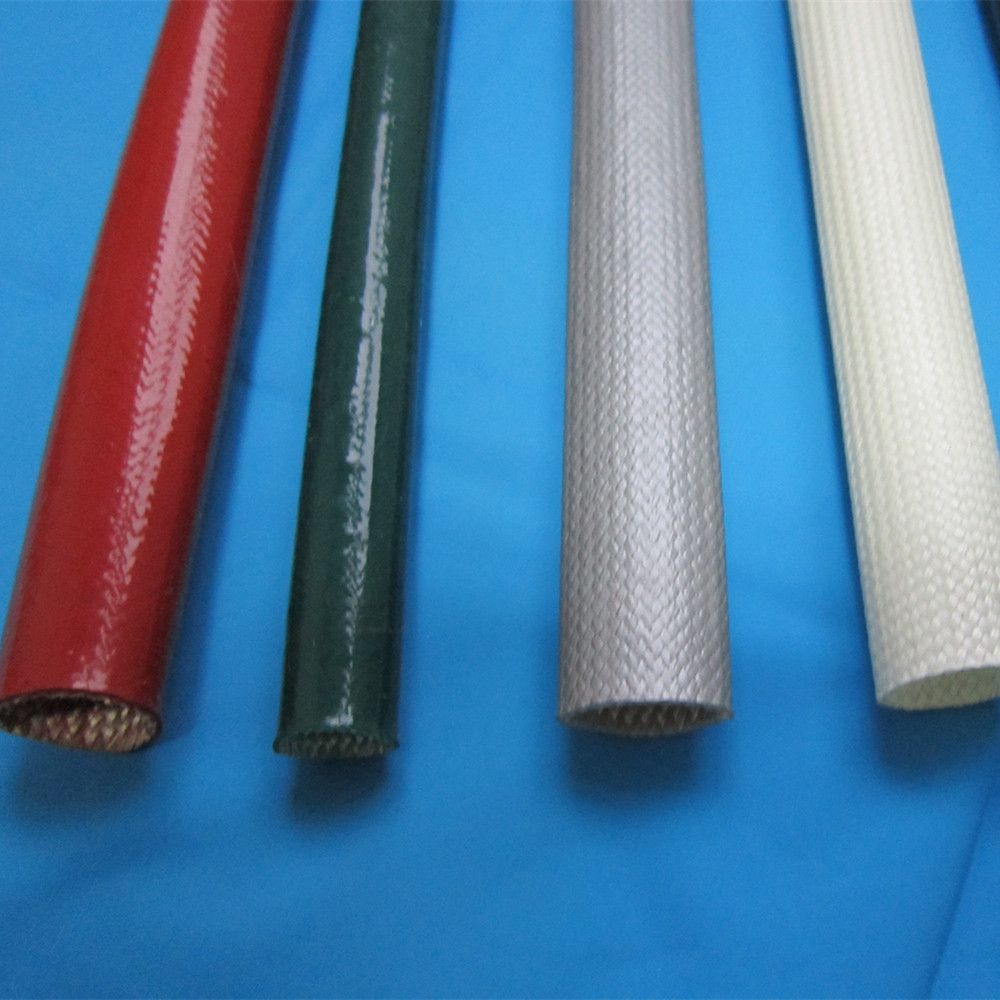

Silicone Coated Fiberglass Sleeving is a highly versatile and durable protective solution designed to offer exceptional insulation and resistance to high temperatures. Combining the strength and flexibility of fiberglass with the heat-resistant properties of silicone, this sleeving is ideal for a wide range of applications across various industries. It ensures optimal protection for wires, cables, and hoses in demanding environments, providing long-lasting performance and reliability.

Key Features:

Industry Applications:

Automotive Industry: Silicone Coated Fiberglass Sleeving is commonly used in automotive wiring, hoses, and cables to protect them from extreme temperatures, oil, and abrasion. Its high heat resistance ensures the longevity and reliability of electrical systems and fuel lines.

Aerospace Industry: The aerospace industry requires materials that can withstand extreme conditions, including high temperatures and mechanical stresses. Silicone Coated Fiberglass Sleeving is used to protect aircraft cables, fuel lines, and hydraulic hoses in harsh environments.

Marine Industry: In the marine industry, silicone coated fiberglass sleeving is used to protect cables, wiring, and hoses in engine rooms and other high-heat areas. It ensures that systems function smoothly even in harsh marine environments, where exposure to saltwater, high temperatures, and mechanical wear is common.

Oil & Gas Industry: Silicone Coated Fiberglass Sleeving is essential in the oil and gas sector for protecting cables, wires, and hoses exposed to high temperatures, chemicals, and mechanical wear. It helps prevent failures in critical systems and equipment used in drilling, refining, and transportation.

Power Generation: In power plants and energy facilities, this sleeving is used to protect cables, wires, and hoses exposed to high temperatures from steam, exhaust, and hot equipment. Its excellent insulation properties help maintain safe and efficient power generation systems.

Industrial Manufacturing: Silicone Coated Fiberglass Sleeving is widely used in industrial manufacturing environments to protect machinery wiring, hoses, and equipment from heat, abrasion, and chemical exposure. It helps ensure the continued performance of production systems in extreme conditions.

Fire Protection: Silicone Coated Fiberglass Sleeving is used in fire protection applications to insulate fire alarm cables, sprinkler system wiring, and electrical components exposed to potential fire hazards. Its flame-resistant properties help reduce the risk of electrical fires in critical systems.

Construction Industry: The construction industry uses this sleeving to insulate and protect electrical wiring and piping systems in high-heat applications such as boilers, heating systems, and HVAC units. It helps maintain system efficiency and prevents electrical failures.

Conclusion: Silicone Coated Fiberglass Sleeving is an essential material for providing superior protection in industries that require heat, flame, abrasion, and chemical resistance. Its durability, flexibility, and excellent thermal insulation properties make it ideal for automotive, aerospace, marine, oil & gas, power generation, industrial manufacturing, and fire protection applications. Whether you're insulating cables, wires, or hoses in extreme conditions, this sleeving offers long-lasting, reliable performance across a wide range of demanding environments.